PRODUCTS

IN-RACK AIRFLOW

SYSTEMS

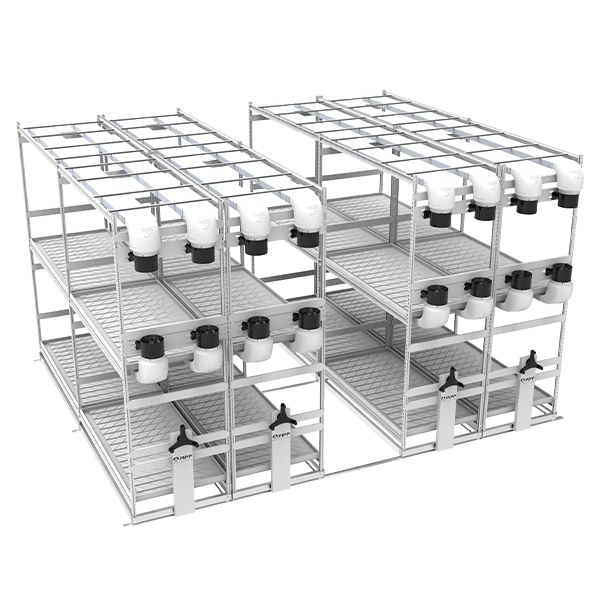

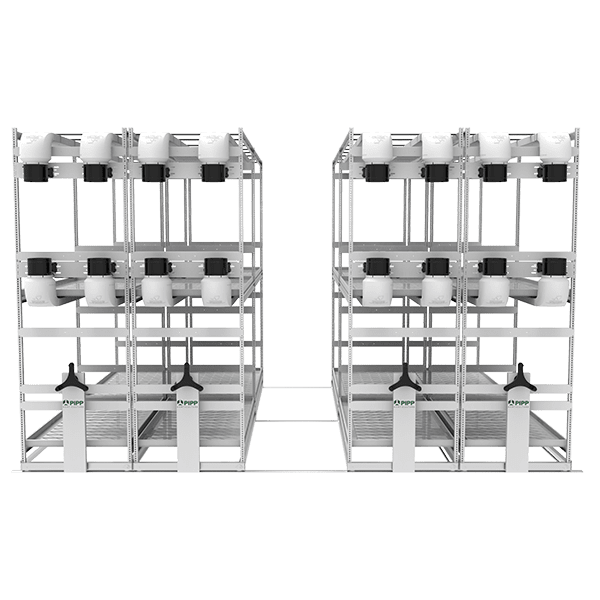

Effective and consistent air circulation is a must for any successful vertical farm. Fixed or oscillating fans provide uneven air movement and require complicated electrical sourcing. The VAS In-Rack Air Circulation System allows for consistent airflow, and its unobtrusive design disappears alongside the grow lights under the upper rack.

When to Use VAS In-Rack Airflow Systems

As a division of Pipp Horticulture, Vertical Air Solutions’ patented In-Rack Airflow Systems integrate seamlessly into Pipp’s Mobile Vertical Racking Systems to provide effective and consistent airflow to your plants. As the pioneer of in-rack airflow delivery technology, VAS stands alone as the clear industry leader with hundreds of successful installations throughout the world. With its unique ability to deliver an easily adjustable amount of airflow over the entire plant canopy at all grow levels, while minimizing energy consumption and waste, many of today’s top MSOs and other leading producers have successfully integrated VAS into their vertical grow platforms to ensure optimal plant health.

VEGETATIVE

FLOWERING

THE FUTURE OF AIRFLOW TECHNOLOGY

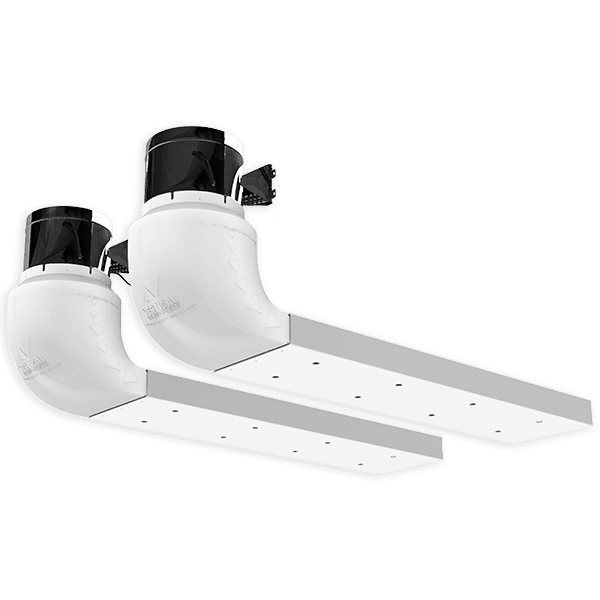

VAS Air Circulation System

Vertical Air Solutions’ patented In-Rack Airflow System provides canopies with uniform, top-down airflow while homogenizing the climate in a multi-layered rolling rack platform. The first purpose-built air circulation system of its kind, developed by growers for growers. Designed to deliver the airflow your plants need to thrive while saving valuable space in vertical farming applications.

The next generation of airflow systems by VAS has arrived. Every component has been fully redesigned and optimized to deliver the highest air velocities possible while maintaining consistent performance across varying row lengths. New materials and construction methods were carefully chosen to simplify installation and reduce costs without sacrificing quality. Highly modular with multiple configurations, this system was designed to meet the airflow needs of your crop.

- EC Inline Fans: Reduces power consumption and allows for granular adjustment of air velocity. EC fans may be eligible for Utility Rebates depending on region and provider.

- Fan Mounting Options: System can be installed with the fans facing up or down. Mounting brackets allow for precise mounting height and adjustment of duct spacing.

- Dual Lofted Plenum Design: Maximizes fan performance and reduces turbulence within the ducts.

- Corrugated Polypropylene Ducts: Humidity-resistant and compatible with common cleaning chemicals but cost-effective enough to replace if desired.

- Optimized Duct Dimensions: Greatly increases flow rates and duct velocities while minimizing turbulence and friction losses.

- Pressure Balanced: Provides equal flow front-to-back and side-to-side at variable row lengths and improves exit angle.

- Air Outlets: improved circular hole pattern for maximum air dispersion, throw distance, and air velocity.

- Thin Form Factor: Thinnest form factor on the market reducing overall system height and saving space.

- Automated Control (Optional): Easily integrate fan controls into common automation platforms for external control of fan speeds.

- Pop-Up Duct: Lightweight, ships flat, and pop-up design for easy installation.

- Increased Consistency: Mitigate microclimates and homogenize environmental conditions for consistent VPD and growth rates.

- Enhanced Crop Health: Maintain even leaf temperatures and facilitate gas exchange to promote transpiration and photosynthetic rates.

- Vertical Airflow: Harness the power of strategic vertical airflow to ensure uniform temperature, humidity, and CO2 throughout your grow space.

- Space-Saving Design: Our compact and sleek system is engineered to fit seamlessly into most vertical racking systems with the thinnest form factor on the market while providing superior performance.

- Increased Savings: Enjoy cost savings and sustainability with this energy-efficient system that maximizes air circulation while minimizing power consumption.

- Customizable Control: Tailor the airflow to meet your plants’ unique needs with adjustable fan speeds and a modular system design.

- Dependability: Invented and field-proven by growers for growers. Designed with a quantitative, science-based approach validated by Computational Fluid Dynamics (CFD) and physical testing.

- U.S. Patent No. 10,694,682 B2

- U.S. Patent No. 10,806,099 B2

- U.S. Patent No. 11,632,915

- U.S. Patent No. 11,641,810

- Other U.S. and foreign patents are pending.

- Vegetative

- Flowering

Proud Division of Pipp Horticulture

Pipp has dominated the Mobile Storage Industry for over 40 years and they carried that same passion and innovation over to Vertical Air Solutions™. With Pipp’s experience in equipment sales and manufacturing backing them, Vertical Air Solutions™ has become an industry-leading provider of In-Rack Airflow Systems and products for the indoor vertical farming cannabis industry globally.

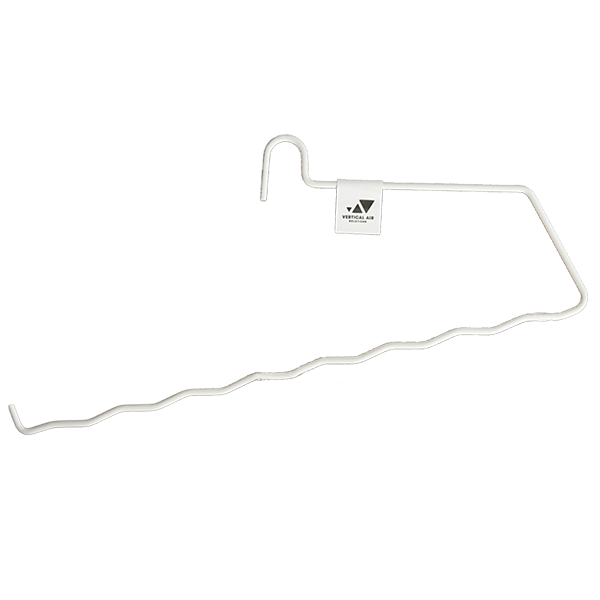

CUT HANGING TIMES IN HALF

VAS Plant Hangers

Vertical Air Solutions’ Plant Hangers specifically target the needs of cannabis cultivators. With an opening on one side, stalks are placed directly on a horizontal bar, instead of being threaded through the hanger. These hangers are also taller to allow for longer base stems, and the indentations on the horizontal bar keep the plants equidistant from each other, assuring even drying and consistent yields. The sturdy, anti-microbial construction of the hangers allows for years of re-use. When combined with rolling racks that can be weighed and go straight from the flower room to the drying room, the plants are touched only one time, reducing the risk of damage.

- More efficient use of labor and space by minimizing handling of the plants and having more plants per hanger.

- Less waste due to fewer flowers being lost from multiple handling operations.

- Even drying rates for all plants, assuring a consistent product for manufacturers and users.

- Cost savings and a lowered environmental impact from the continuous re-use of the production-tested anti-microbial steel hangers.

- Hanger Dimensions: 19.2” width | 8.75” height | 1.5” hanger hook width

U.S. Patent No. US D873,036 S

- Harvesting

- Drying

PRODUCTS

See Them in Action

FREE RESOURCES

Want to Learn More?

Download the Vertical Air Solutions Flyer to learn more about their product offerings and feel free to reach out to our sales team with any additional questions that you may have!

Cannabis Life Cycle

Pipp Horticulture has developed a variety of products to help operators throughout the entire seed-to-sale cycle. Review the steps below to see which Pipp products assist during each phase of the cultivation cycle.

CLONE ROOM PRODUCTS

HARVESTING PRODUCTS

CURE & STORAGE PRODUCTS