RESOURCES

STAY IN

THE KNOW

Stay informed about the latest updates on cannabis news, harvesting cannabis, and discover expert tips for maximizing your grow space by regularly checking our blog and tuning in to the Cultivation Elevated® Podcast!. Stay ahead in the cannabis industry by staying connected with our comprehensive content.

Frequently Asked Questions

Below are a few commonly asked questions about our Mobile Vertical Racking Systems. Want to learn more? Reach out to our sales team for more information!

How many rows can I move at one time?

It depends on length and height of rows, but on average three or four rows can be moved at once.

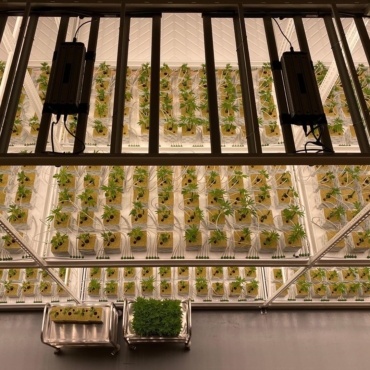

How many plants fit on each grow tray?

The standard is 36 plants per 4x8 grow tray. However, every group is unique in how they grow.

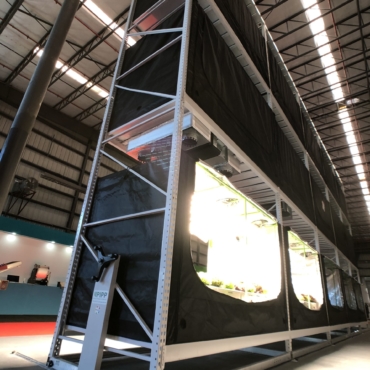

How tall can the racks be?

Mechanical-Assist Cultivation Systems can be built up to 16' high and 56' long. Systems larger than this would require engineering approval.

What kind of track and rails are used? How are they installed?

Our unique track and rail system is made of marine-grade aluminum and stainless steel. It is only ½" high and includes an anti-tip feature to comply with seismic codes. We level and anchor the rails into concrete floors for a high quality, safe installation that performs for decades.

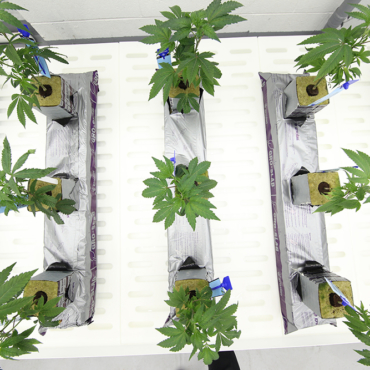

What about irrigation and drainage?

Irrigation and drainage equipment is typically provided by the end user. Our systems can be designed to accommodate a wide range of applications.

Can vertical grow racks tolerate the conditions of a grow room?

Yes. However, prolonged exposure to excessive humidity levels (+55% RH) and direct contact with water can eventually cause corrosion and/or oxidation over time. These are merely cosmetic and do not compromise the strength and durability of the grow system. Routine cleaning and maintenance of the system is the best way to mitigate this risk and maximize the system's performance and longevity.

Latest From Our Blog

Stay up-to-date with our latest news and grower tips!

![📣 [MJBizCon RECAP] 📣 Wait until you see what we have in store for the year ahead! 🤯](https://pipphorticulture.com/wp-content/uploads/2022/02/IMG_3510-370x370.png)