How to Build a Flower Room For an Indoor Cannabis Facility

What You Need To Know About Your Cannabis Flower Room

The flower room is the soul of the indoor cannabis facility. It’s where all tours with business partners and excitable local press corps members ultimately culminate, garnering wide-eyed looks of excitement. It’s where all the best traits of a cannabis cultivation company are on display. But those moments only scratch the surface of those rooms’ capabilities. The flower room is where a cultivation business turns plant material and ambition into revenue and growth.

So, what sets any cannabis flower room apart from one another? Aside from the people working in those rooms, there are several fundamental aspects of good flower room design that must be accounted for in the early planning stages–and optimized on a regular basis once operations have commenced.

Consider:

- Spatial Configuration and Plant Density

- Integrated Environmental Control Engineering

- Proper Air Flow and HVAC

- Light Mapping and Design

- Irrigation and Fertigation Infrastructure

Get those core concepts wrong, and your team will miss out on opportunities for stratospheric growth and output. Get them right, though, and you set yourself up for success. After all, what comes out of your cannabis flower room is all about what goes in.

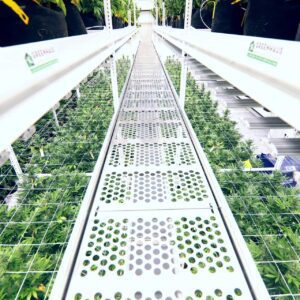

Spatial Configuration and Plant Density

Consider mobile vertical racking systems to maximize this density while preserving the room’s foot traffic flow. You won’t waste an inch of space by adding mobile carriages to your vertical racks, which eliminates fixed aisles between each rack. Mobile carriages will also provide a degree of flexibility when it comes time to expand your canopy or revisit your floor plan outright. Even the best-laid plans in indoor cultivation will be amended as your team hones their operation. By investing now in a more mobile solution, you’ve just bought yourself some serious room to grow in the future.

Plan to fill out those vertical racks with grow trays that allow you to seamlessly connect the technology that we’ll get into in a moment: your lights, your airflow, your irrigation. Picking the right grow tray might seem like a small step, but it’s a fundamental part of your workflow.

WANT TO LEARN MORE? Design your own grow space with Pipp’s Room Generator Tool!

PRO TIP: Different genetics result in different phenotypes. If you’re considering a fairly diverse portfolio of cultivars, implementing vertical racking will allow you to place smaller plants higher, leaving more room on lower racks for taller plants. This height disparity can get very tricky when you’re managing airflow and lighting across a single plane of benches.

Integrated Environmental Control Engineering

It’s not enough anymore to have functioning environmental controls. The competitive nature of the cannabis marketplace insists that operators implement some form of integration and automation into their systems. Your team needs real-time data. As you design and build your flower rooms, you must plan for this integration.

Your team will be in and out of your flower rooms, scouting individual plants, but so too will your environmental control systems analyze real-time data and identify trends among your crops. How are your plants responding to subtle changes in lighting or airflow? Which individual plants are receiving too much or too little light at a given moment? That data, as one minor example, is critical to understanding your flower room. By leveraging this data, growers can fine-tune their environmental parameters for optimal yield and quality.

So, where should your team begin? Develop your flower room design around programmable logic controllers (PLCs) that automate environmental inputs on a real-time basis. Ensure that your sensors are appropriately placed around the room to provide those PLCs with a comprehensive data set. Most data collection can also be conveyed via a given software provider’s app, allowing you and your team immediate access to real-time data and, of course, to sudden emergencies. This data can and should inform your cultivation decisions. Understanding that app should be an important part of your cultivation team onboarding process.

Every plant coming out of your flower room represents a small portion of your company’s bottom line. The data you’re receiving about how those plants are growing can help your team make decisions about what to grow and what to sell (and when to sell). This data collection allows a savvy cultivation team to draw a competitive flower room edge.

Proper Airflow and HVAC

Good air circulation can go a long way toward preventing the spread of more nefarious problems like pests and pathogens. Your HVAC system must exchange the air in your flower room several times per hour, balancing clean oxygen and CO2 levels for optimal plant growth. This means that your HVAC system will be working constantly in the background, so efficiency in your hardware is key.

Use HEPA filters in your ventilation system to remove any airborne pathogens. Indoor cannabis cultivation spaces, no matter the square footage, must be paragons of cleanliness and sanitation. If you’re designing a room as part of a new build, you can incorporate this from the start.

Retrofit projects come with much more pressure on this particular point. Make sure the actual room you’re planning as a future flower room has the HVAC and ventilation capabilities to house flowering cannabis plants safely. Always bear in mind that we’re talking about plant material grown for human consumption.

WANT TO LEARN MORE? Vertical Air Solutions’ patented In-Rack Airflow System provides uniform airflow in a multi-layered rolling rack platform.

Establish a regular maintenance schedule to keep that ventilation system as clean as can be. Delegate specific maintenance responsibilities to team members on a rotating basis so that everyone can dial in their understanding of the system. When it comes to energy efficiency, HVAC is one place where you can really invest for long-term savings. Work with your equipment provider to identify energy-efficient units and map out the cost of those units over time.

PRO TIP: Manage heat load from other pieces of equipment (more on lighting in a moment) and measure the capacity required to maintain a consistent temperature and humidity level in the room. Variable-speed fans can provide the flexibility needed to maintain those levels throughout the day.

Light Mapping and Design

As you’ve noticed thus far, a keyword in flower room design is “consistency.” You can use software to map a room’s light intensity. This will give you a more refined picture than simply using your own eyes to gauge your room’s setup. You need to understand how much light a given plant is going to receive from all light fixtures that “touch” it. These programs coordinate each spot’s given light intensity by measuring light from as many as nine angles around the plant. This will give you a better sense of the uniformity of your light distribution. Much like you can avoid microclimates with uniform airflow, you can avoid hot spots with uniform lighting.

Get familiar with the calculator for photosynthetic photon flux density (PPFD) and ensure that you’re covering the canopy. Within that coverage in your flower room, you want to recreate the sun’s own diurnal rhythm as closely as possible. While your veg room will operate on something close to an 18/6-hour cycle, your flower room will be on a 12/12-hour cycle of darkness and light. (Consider, too, the potential power of inter-canopy lighting.)

PRO TIP: Be mindful of light pollution streaming in from hallways. It might not seem like a big deal when so many more consequential investments are being made early on, but photons leaking in from the hallway can have an outsized impact on your plants’ health. As an added precaution, consider using green light spectra (near 530nm) in the hallway outside your flower room(s) to limit any problematic spillover effects.

Irrigation and Fertigation Infrastructure

Once again, consistency will drive this facet of your flower room plan. Automated drip irrigation systems or hydro setups can deliver uniform amounts of water and nutrients to each plant with minimal interruption to the floor plant mentioned in the previous section. You don’t need hoses lying around your flower room; you need solutions.

Within those systems, make sure your environmental controls include monitoring of pH and electrical conductivity (EC) to continue that consistent nutrient delivery. Overwatering, underwatering: Nothing good comes from being imprecise with your irrigation system.

Cannabis Flower Room Efficiency Checklist

Regularly check and maintain the HVAC and ventilation systems to ensure the CO2 supply is working correctly. Systematize this process as part of your team’s SOPs.

- Inspect your lighting fixtures, first through your environmental control data and then by physically examining any units that need maintenance. Clean them regularly.

- Same with your fan units: Keep the room’s air moving efficiently by maintaining fans and air filters regularly.

- Maintain a highly detailed sanitation protocol.

- Ask your cultivation team members what they think about the literal floor plan: How easy is it to get their jobs done within the flower room(s)?

- Check your irrigation and fertigation systems for any unexpected issues, and ensure your plants get the right amount of nutrients.

- As a senior-level management team, periodically review how well your flower room is running and look for ways to save energy and resources.

- Ensure all team members are well trained in your company’s flower room safety SOPs and regularly review and update operational procedures.

Regularly check and maintain the HVAC and ventilation systems to ensure the CO2 supply is working correctly. Systematize this process as part of your team’s SOPs.

Regularly check and maintain the HVAC and ventilation systems to ensure the CO2 supply is working correctly. Systematize this process as part of your team’s SOPs.