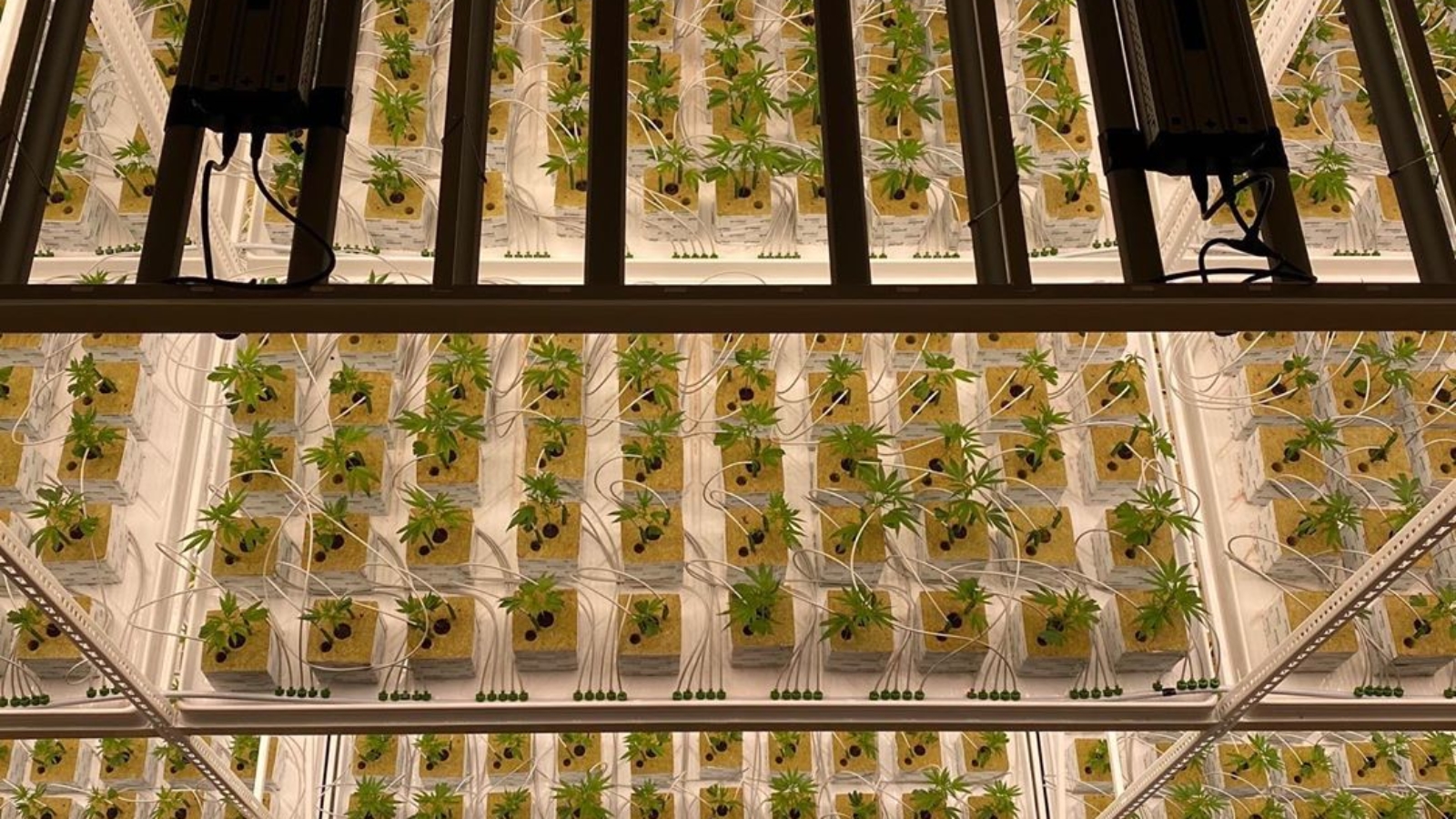

The vertical farming industry is growing every day. Grand View Research estimates that the global vertical farming product market will grow by 25.7% by 2027. With growers in food innovation, cannabis, and specialty crops, essential tools are required for a successful growth system. Of these tools, mobile vertical racks are critical. When choosing a mobile vertical rack provider, there are several things that need to be considered when researching solutions.

Specifically for cannabis cultivation, mobile vertical racks can make a difference in yields and annual revenue. Reviews and word of mouth can help provide guidance when choosing a vertical rack provider, but the research should not stop there. Here are 6 things that need to be considered when evaluating the companies that manufacture, design, sell, and install these facility-transforming systems.

#1. Dedication to The Horticulture Market / Education

Are they committed? This is a question that needs to be considered immediately. A large investment of time and money is made when building and designing a facility plan and all the elements that make up a system. Mobile vertical rack system technology is newer to the industry and is growing rapidly. Because of this growth, there are companies that have cut corners in order to get to the market faster. This can result in mobile vertical racks that are untested and undeveloped, all to capitalize on this dynamic market at your expense.

A provider needs to show commitment to the industry and it starts with providing value. This means producing and delivering quality products, service, installation, R&D, and innovation. To achieve the most competitive price points requires years of operational systems refinement and product development. There are few companies that will meet this requirement, and if they do, it’s time to look deeper at their commitment to the customer. Warranties, customer service, engagement with growers on a regular basis?

A mobile vertical rack supplier needs to align themselves with their customer and the needs of the ever-changing indoor farming industry. If your supplier lacks a clear presentation of their dedicated (horticulture) market knowledge base showcasing their work product, satisfied customers, product developments and industry-specific content, it may be a sign that they are not advancing in the space and are not committed long-term. Even more specifically, does your mobile vertical grow racking systems partner simply add “Horticulture” or “Vertical Grow Racks” to their list of many other markets served, or have they developed a dedicated team that is focused on this application exclusively, properly branded, and thoroughly presented. Any viable option in this space, at this time, should be able to point to numerous installations rather than repeatedly showcasing a single project.

#2. Innovation

Closely linked to no. 1 above, are they innovating? Are they leading the charge to provide growers with tools that will enhance their yields? Innovation is a word that can easily be thrown around. Everyone thinks they are innovating, but what is the true definition of innovate? The definition is: to introduce something new; make changes in anything established. This is especially true when introducing new methods, ideas, or products. As mentioned above, there are more and more players coming to the table with vertical racks but what sets them apart? PIPP Horticulture is making an effort to continuously innovate.

For example, in February PIPP announced The ELEVATE™ Platform System. Outside of its robust, lightweight, and portable deck, it was designed with the customer in mind. Innovation can come with a lot of bells and whistles, but ultimately, innovation is about the customer. When considering a vertical rack provider, look beyond the flashy and make sure that innovation is centered on the customer experience.

#3. Lead Times & Made in the USA!

Facility developers and operators are great at asking questions about price upfront and early, but what about lead times? This can be equally or even more critical to the successful outcome of a cultivation project launch. In order to avoid 2, 3, or 4 months delays, lead time needs to be considered. There are many phases of a project that need to be taken into account when understanding lead times. The first phase is the time it takes to receive the product for the build. This is a key part of the timeline when working towards the start of an operation, but what about the post-build (operational phase)? If product lead times are beyond industry standards, replacement parts, expansion orders and general support may be challenging. A trustworthy provider will design, manufacturer, ship, and install a system in a reasonable amount of time. Although current lead times have been extended for all manufacturers, Pipp Horticulture’s products and materials are USA made & sourced, therefore the transportation challenges with importing containers affecting many other manufacturers are a non-issue for our clients.

For example, Pipp Horticulture’s High-Density Mobile Vertical Racking Systems and Solutions are made in the USA and typically have a lead-time of 3 to 5 weeks. (at the moment, lead-times are extended due to economic variables in the supply chain). Based on the industry, this is considered a reasonable lead time. If a provider is making estimates that are longer, it’s worth looking at other options. It is important to also note that as a grower, after set-up or the initial installation, modifications are possible. As these occur, working with a provider that is located in the USA and has an established US-based supply chain (sourcing materials domestically) ensures quick responses resulting in quick solutions.

#4. Integrated Tray System

There are many elements that make up a fully operating vertical rack system. Items to consider vertical grow racks, carriage track systems and grow tray systems. For many providers, these items are separately sourced which can add a layer of complexity when developing a functioning system. There are providers that are leading the way in this space, and developing integrated tray offerings. With a tray system specifically designed to work in unison with the racks, it can enhance performance, reduce cost, and enable a more seamless purchasing, fulfillment and operational experience.

An integrated tray system does not require separated components to support the trays. The supports are part of the racks and help to optimize the integration of other critical equipment (lighting, airflow, drainage…). These components are worth the research and should be evaluated when choosing a provider.

#5. The Drive System

The days of rolling casters are long gone and technology has evolved. When selecting a new system, it’s important to ask the provider whether a ‘continuous drive shaft’ is a standard feature in their mobile rack systems. For exceptional quality and a highly functional mobile racking system, an all-wheel-drive carriage, aka continuous drive shaft, is the optimal choice.

In a system that does not have a continuous drive shaft, one end of the carriage moves before the other. This continuous friction between the wheel and the rail can destroy the equipment over time, impeding movement and ultimately leading to failure. If this is not taken into consideration the carriage movement will be difficult at best risking the efficiency of an operation.

#6. Sales, Installation & Service

There is a popular saying in the industry, “the quality of the installation & support is just as important as the quality of the product!” And it’s popular because it is true.

Start the consideration process early to allow time for research and referrals. Reach out to other like-minded cultivation companies and ask questions. Gathering information will be the greatest asset in the consideration process. Here is a series of questions that can help:

- What was the installation like?

- Do they provide on-demand service nationally?

- What is the structure of the provider’s ongoing support?

- Is their installation department managed by a dedicated corporate team?

- What is their level of experience with mobile vertical racking installation specifically?

- How many systems have they installed?

It’s important to know that support is available and that quality is apparent. But most of all, the customer has to be the provider’s primary focus. PIPP Horticulture is a dedicated mobile vertical rack provider with a trained and certified staff located throughout the US and Canada. With more than 40 years of experience in the mobile racking industry, PIPP Horticulture is not just a provider, but a partner. Our certified installation team and cultivation experts are driven to provide industry leaders with custom solutions that help the industry grow. Learn more about PIPP installations and our dedication to the industry by downloading one of our latest case studies: https://pipphorticulture.com/resources/

In Conclusion

Now that you’ve made it this far, you’re probably getting a good idea of which option (drying racks or carts) might work best for your grow space. For assistance in selecting the best drying solution for your operation, download our latest e-book or contact the team at PIPP Horticulture today!