Site Selection for a New Cannabis Grow Facility

Your team is gearing up to build a cutting-edge cannabis cultivation facility, and you’re collaborating with a design team to ensure meticulous planning and execution every step of the way. Proper site selection is one of the most crucial decisions to make in the early stage of the process. Taking a thoughtful approach to choosing your site can prevent costly upgrades and compromises later on.

So, how do you identify that ideal site for your facility?

As Pipp Cannabis Operations Specialist Anders Peterson said in a recent webinar, it helps to move methodically through a checklist of sorts, covering utilities, structural support, climate considerations, and fire code compliance. Schedule meetings with all your stakeholders to confirm that your checklist aligns with local regulations and business goals.

Let’s get into it…

Initial Site Considerations

#1: Utilities

Before committing to a location, assess the available utilities. After all, you need a great deal of power to run your operation, and you’ll want to consider any long-term expansion plans for your business.

Peterson said that, in most cases, your team will need to augment your site’s power capabilities. “More often than not, you’re going to have to run additional power to these facilities, sometimes gas,” he said. “Most commercial buildings today just don’t have the infrastructure that indoor grows need. That’s why it’s good to locate a building close to a denser area that has a pretty established grid.”

Conduct a thorough load assessment to verify the availability of three-phase electrical connections for HVAC systems, grow lights, and irrigation.

If natural gas is required for heating or CO2 enrichment, consult with local utility providers to determine whether extending existing gas lines is feasible.

For water supply, perform a pressure test to ensure the system can meet the demands of irrigation.

Action Item: Obtain blueprints from the utility companies for an accurate understanding of the current infrastructure.

#2: Structural Support

Bear in mind that most commercial building roofs weren’t designed to support controlled environment agriculture (CEA). Get out in front of that problem as early as possible.

“Most of the roofs on commercial buildings aren’t designed to support the heavy HVAC equipment required for indoor cultivation,” Peterson said.

Have your team perform a roof load analysis to check the live load capacity and consider ground-level equipment installation to reduce pressure on the roof. Plan space around the building for generators, chillers, and fans without obstructing parking or delivery access. Work the space from all angles (building needs, people needs, plant needs).

Action Item: Hire a structural engineer to inspect the roof and foundation for load-bearing capacity.

#3: Climate Impact

The local climate will affect your HVAC system’s efficiency. Now, your business may be tied from the get-go to one climate over another. (Let’s say you’re bound to the state-licensed market in Ohio, for example, or Connecticut. California may be another story entirely.)

Extreme temperatures, humidity, and seasonal changes can greatly impact HVAC efficiency and performance. Consult historical weather data to adjust HVAC system sizing and ensure you can maintain ideal room conditions.

Action Item: Obtain historical climate data and cross-reference with HVAC specifications to confirm equipment performance under expected conditions.

Specific Site Selection Factors

#1: Floor Condition

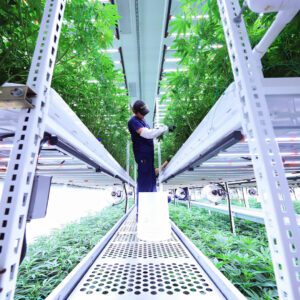

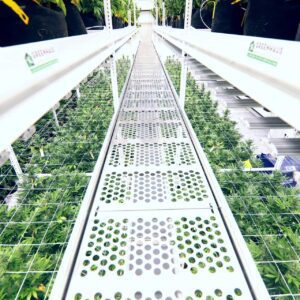

Multi-level mobile racking requires a strong foundation. “You need to make sure that the foundation is good and well-suited for that application,” Pipp Product Manager Del Rockwell said.

Core drilling can confirm the slab’s depth and uniformity for supporting mobile racking. Cracks or uneven surfaces can undermine stability. If flaws are identified, consider resurfacing or replacing the slab with high-strength concrete.

Action Item: Commission a geotechnical survey and core drilling to verify the slab’s condition and calculate necessary repairs.

#2: Column Spacing

Column spacing impacts mobile racking layouts, so get a good sense of the literal square footage available on the floor.

“Column spacing … can cause a lot of issues with laying out the racking.,” Rockwell said.

Plan for a minimum 40-foot span to minimize obstructions and provide ample support for overhead systems. Conduct a structural analysis to ensure the columns can withstand extra loads from HVAC equipment and irrigation piping.

Action Item: Create or study detailed blueprints indicating column positions and calculate load capacity before designing the rack layout.

#3: Ceiling Height

The ceiling height must accommodate multi-level cultivation tiers. “Ceiling height can absolutely cut off your headspace and eliminate some cultivation tiers,” Rockwell said.

Ideally, the ceilings should be at least 16’ to accommodate multi-level racking. But they can be installed in spaces with as little as 10’ high ceilings and tighter spacing between grow levels.

Confirm the clear height for multi-tier systems and assess whether mezzanines or beams will obstruct usable space. Plan for ductwork, lighting, and irrigation systems to maximize growth potential.

Action Item: Use laser measurement tools to map out the usable height for each rack tier, adjusting for overhead equipment.

Fire Code Compliance

#1: Local Regulations

Engage with the local fire marshal early to ensure the facility adheres to local fire codes. Local community communication is paramount in those early days.

“Try to do everything you can to make that a smooth interaction,” Rockwell advised.

Network with other cultivators who have successfully navigated the local fire codes to identify common issues and best practices.

Action Item: Schedule a preliminary consultation with the fire marshal to review plans and obtain feedback on compliance strategies.

#2: National Standards

Monitor the progress of NFPA 420, the National Fire Protection Association’s new standard for cannabis cultivation. Sign up for proactive email updates, too. Stay updated on regulatory changes to ensure your facility is compliant.

Action Item: Sign up for the NFPA newsletter to receive updates and download relevant guidelines.

Conclusion

Planning a new grow facility requires collaboration between experts, clear communication with regulators, and careful analysis of utilities, structural support, and fire safety.

By considering floor conditions, column spacing, ceiling height, and HVAC loads early in the process, facility managers can minimize delays and create a highly efficient and compliant grow facility that thrives.

The Inverse Square Law

The Inverse Square Law Tailoring Spectra with LEDs

Tailoring Spectra with LEDs Optimizing Vertical Rack Design

Optimizing Vertical Rack Design Addressing the Lower Canopy Challenge

Addressing the Lower Canopy Challenge

Ukraine’s medical cannabis law will take effect later in the summer of 2024; in the meantime, Parliament will draft more specific regulatory language. Imports will be a critical source of the country’s cannabis supply, echoing other European countries’ paths to a legal market.

Ukraine’s medical cannabis law will take effect later in the summer of 2024; in the meantime, Parliament will draft more specific regulatory language. Imports will be a critical source of the country’s cannabis supply, echoing other European countries’ paths to a legal market.

However, the path to expansion is not without its hurdles. International treaties and the U.S.’s own complicated relationship with cannabis will complicate any expansion plans for growers or retailers with an eye toward Europe.

However, the path to expansion is not without its hurdles. International treaties and the U.S.’s own complicated relationship with cannabis will complicate any expansion plans for growers or retailers with an eye toward Europe.

Creating a FIFO structure to your

Creating a FIFO structure to your  Continuing with the helpful dispensary inventory management acronyms, let’s address Just In Time (JIT) inventory systems.

Continuing with the helpful dispensary inventory management acronyms, let’s address Just In Time (JIT) inventory systems.

“

“ Your facility runs on the efficiency of its environmental control system, but you must add a layer of redundancy by personally checking on the actual variables (temperature and humidity, foremost) on a regular basis. Automated systems are fine and increasingly prevalent, but your team should not solely rely on them. The value of the plants in your cannabis mother room is simply too great.

Your facility runs on the efficiency of its environmental control system, but you must add a layer of redundancy by personally checking on the actual variables (temperature and humidity, foremost) on a regular basis. Automated systems are fine and increasingly prevalent, but your team should not solely rely on them. The value of the plants in your cannabis mother room is simply too great.

Perhaps more than any other room in your facility, the

Perhaps more than any other room in your facility, the  Cloning: where the true magic happens in your facility.

Cloning: where the true magic happens in your facility. Lastly, like most other activities in the cultivation space, work in the mother room is an ongoing education. Encourage your team to stay informed on the latest cultivation and genetic trends in cannabis.

Lastly, like most other activities in the cultivation space, work in the mother room is an ongoing education. Encourage your team to stay informed on the latest cultivation and genetic trends in cannabis.

While “yield” has remained a cornerstone metric for cultivation businesses’ success since the dawn of the industry, this basic fact is only becoming more pertinent. Price compression, oversupply, rapidly evolving consumer demand trends: There are factors at play that demand new efficiencies coming out of the flower room.

While “yield” has remained a cornerstone metric for cultivation businesses’ success since the dawn of the industry, this basic fact is only becoming more pertinent. Price compression, oversupply, rapidly evolving consumer demand trends: There are factors at play that demand new efficiencies coming out of the flower room.

The cornerstone of a successful cannabis flower room is its environmental control system. We’ll get into the specifics of HVAC, lighting, and irrigation shortly, but first, we must point out the importance of linking these technologies. Automation and data analytics go hand in hand with the actual horticultural practices of your flower room.

The cornerstone of a successful cannabis flower room is its environmental control system. We’ll get into the specifics of HVAC, lighting, and irrigation shortly, but first, we must point out the importance of linking these technologies. Automation and data analytics go hand in hand with the actual horticultural practices of your flower room.  Airflow

Airflow Lights get the spotlight in cannabis cultivation, and perhaps deservedly so.

Lights get the spotlight in cannabis cultivation, and perhaps deservedly so.  Irrigation and fertigation are critical aspects to your flower room design and to the finished flower you’re harvesting.

Irrigation and fertigation are critical aspects to your flower room design and to the finished flower you’re harvesting.  Regularly check and maintain the HVAC and ventilation systems to ensure the CO2 supply is working correctly. Systematize this process as part of your team’s SOPs.

Regularly check and maintain the HVAC and ventilation systems to ensure the CO2 supply is working correctly. Systematize this process as part of your team’s SOPs.