Master the transition from drying to curing with data‑driven moisture targets, VPD control, and biochemistry insights that lock in flavor and potency.

What Schedule III Really Means for Cannabis: A Lawyer’s Unfiltered Take

Master the transition from drying to curing with data‑driven moisture targets, VPD control, and biochemistry insights that lock in flavor and potency.

Cannabis Cultivation Trends 2026: Facility Design & Efficiency

Master the transition from drying to curing with data‑driven moisture targets, VPD control, and biochemistry insights that lock in flavor and potency.

Unlock the Secrets of Cannabis Storage Regulations in 2026

Master the transition from drying to curing with data‑driven moisture targets, VPD control, and biochemistry insights that lock in flavor and potency.

Maximize Growth by Retrofitting Your Cannabis Facility

Master the transition from drying to curing with data‑driven moisture targets, VPD control, and biochemistry insights that lock in flavor and potency.

GMP vs GACP: What Cannabis Operators Need to Know for 2026

Master the transition from drying to curing with data‑driven moisture targets, VPD control, and biochemistry insights that lock in flavor and potency.

The 18-Plant Standard: Why 3×6 Is the Sweet Spot for Tiered Flower Rooms

Master the transition from drying to curing with data‑driven moisture targets, VPD control, and biochemistry insights that lock in flavor and potency.

The Art & Science of Curing Cannabis: Owning Your Moisture Handoff

Master the transition from drying to curing with data‑driven moisture targets, VPD control, and biochemistry insights that lock in flavor and potency.

The Art & Science of Curing Cannabis: Curing Vessel Strategies for Long‑Term Stability

Choosing the right curing vessel for your cannabis is vital for success and making the wrong choice can drain away your ROI. Keep reading for the top factors to consider…

Timing Your Veg in Multi-Tier Cannabis Cultivation

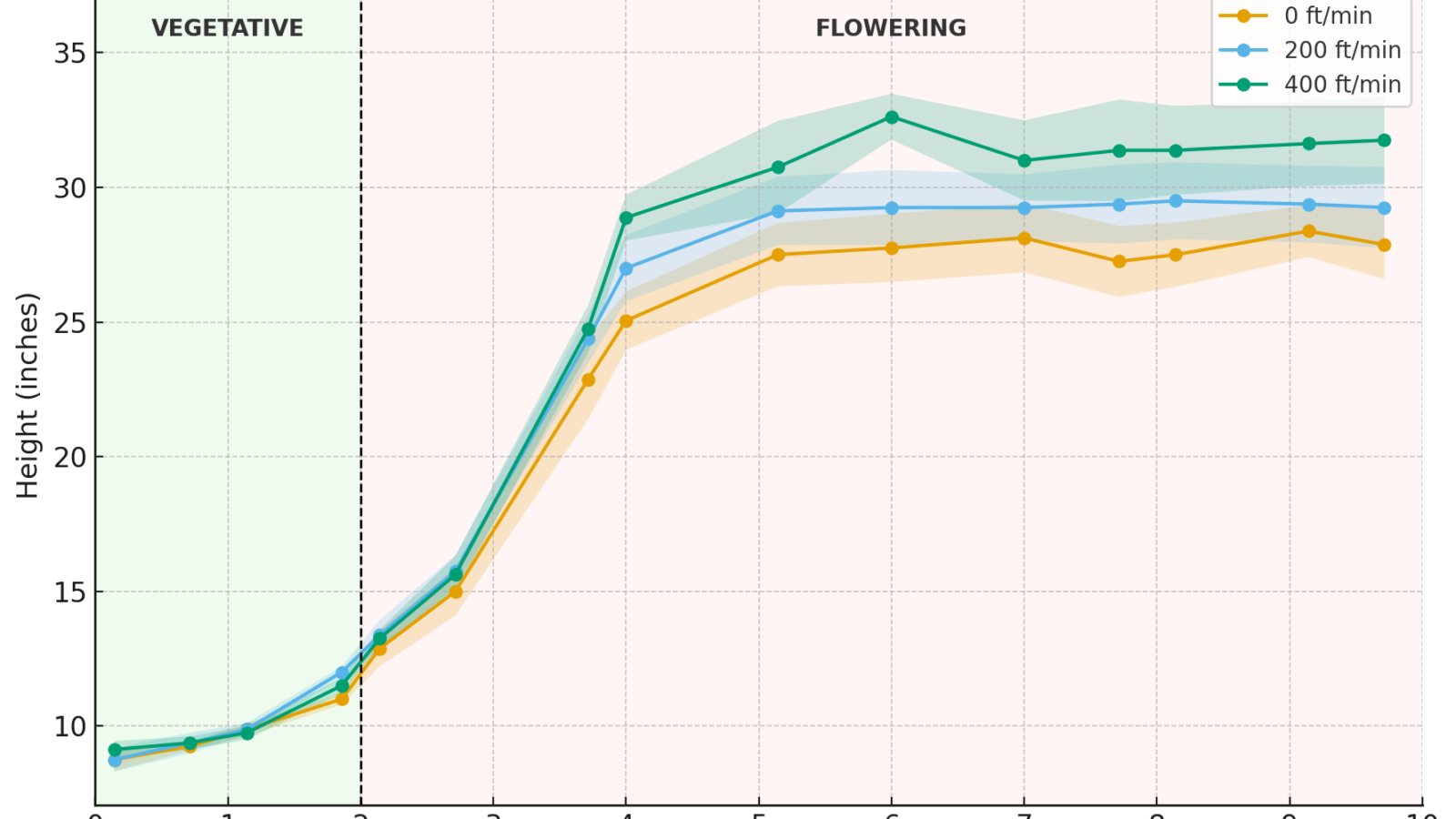

Airflow management is one of the most overlooked variables in indoor cannabis cultivation, yet it is crucial for plant health, yield consistency, and overall operational efficiency.

Many facilities that initially installed horizontal airflow systems may be experiencing microclimate issues, uneven transpiration rates, and inefficiencies that throw environmental conditions out of balance. VAS 2.0, Vertical Air Solutions’ latest upgrade, is designed to correct these inefficiencies with improved energy efficiency, modular control, and a lighter, easier-to-install system.

VAS 2.0 presents a practical retrofit solution for growers looking to optimize their airflow without completely overhauling their facility. It aligns airflow with plant biology rather than working against it.