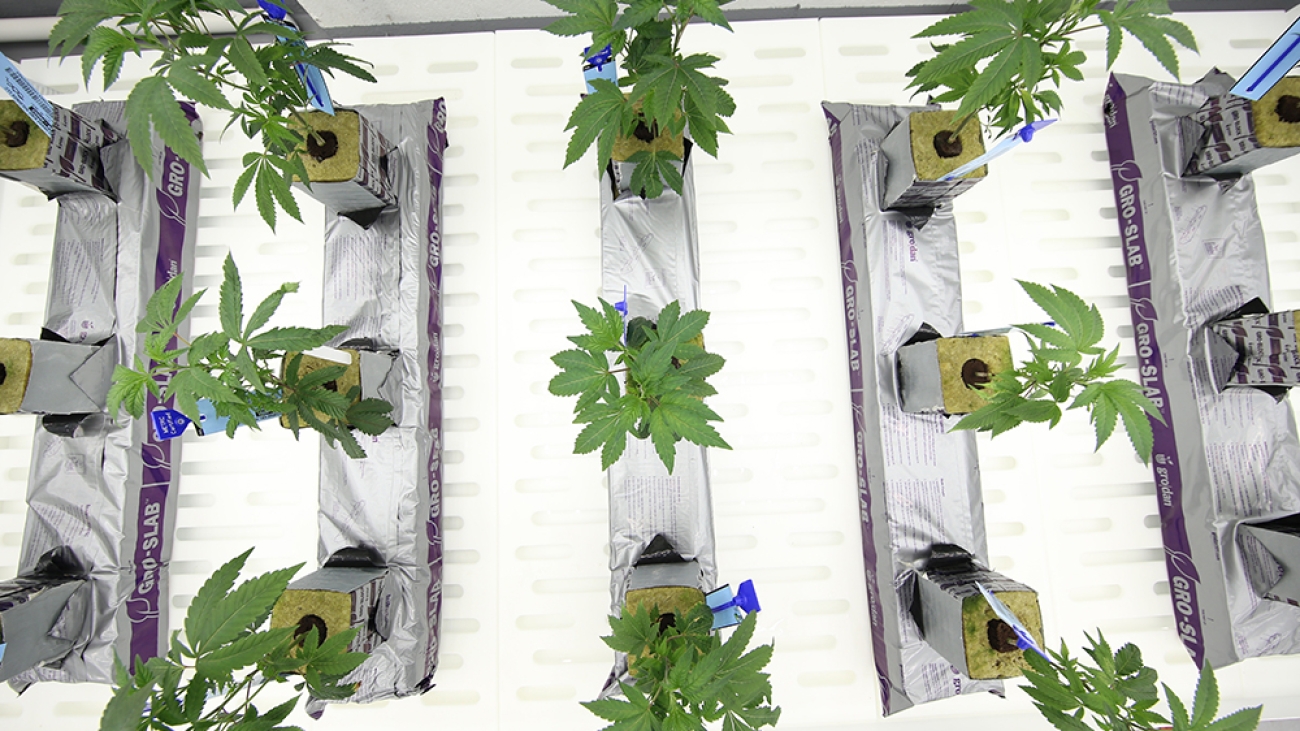

Successful cannabis cultivators are experts at growing, curing, and marketing their products. With years of practice and hands-on experience, they’ve mastered the ways of the plant.

But, what is their secret?

Curing cannabis is a critical step that can make or break the post-harvest process. While cultivation lays the foundation for potency and flavor, curing preserves these valuable cannabinoids and terpenes, leading to consistent results, enhanced flavor, increased shelf life, and a clean burn.

Whether you’re striving for the smoothest smoke or the most aromatic bud, the right curing techniques will allow your cannabis to reach its full potential.

What Is Proper Cannabis Curing?

After spending months growing quality crops, you want to ensure your efforts satisfy consumers. Done correctly, curing protects secondary metabolites and maintains a water activity between 0.55 and 0.65. This process also prevents mold formation, extending shelf life and safeguarding the hard work invested during cultivation. While curing is often described as a combination of science and art, CEA HVACD designs, controls, airflow systems, and racking refinements are the basis for SOPs that achieve predictable results. Without proper care during cultivation, harvest, and curing, flowers can become damaged and potentially require remediation. Here are just a few ways improper curing can affect final products:- Loss of potency: Excessive exposure to light and heat can erode cannabinoids, thus reducing the overall potency of your product.

- Harsh inhalation: Smoking dried-out (low moisture content) cannabis is like inhaling a spoonful of cinnamon – incredibly irritating for your throat and lungs.

- Undesirable flavor: Drying too fast prevents enzymes from working and can trap chlorophyll in the final product creating underwhelming or offensive flavor.

- Risk of mold: Too much moisture inside the curing space creates an ideal habitat for mold and nasty bacteria that render your product unsuitable for consumption.